Protection devices - Circuit breaker and fuse

Electrical protection devices play a fundamental role in ensuring the safety and functionality of electrical systems, acting as preventive barriers against a range of risks associated with the use of electrical energy. These components or systems are meticulously designed to detect, interrupt, or mitigate failures, short circuits, overloads, and other anomalies that could compromise the integrity of electrical installations, connected equipment, and, most importantly, the safety of individuals interacting with these systems.

The importance of these devices lies in their ability to prevent severe consequences, such as electrical fires, irreparable damage to sensitive equipment, and, above all, electric shocks that can endanger lives.

Among the most common protection devices are circuit breakers, which act as automatic switches, shutting off the circuit when they detect an electrical current exceeding safe limits. Fuses, on the other hand, are components that melt in the event of an overload, interrupting the flow of current.

The proper selection and installation of these devices require specialized technical knowledge, as they must be sized according to the specific characteristics of each installation, such as electrical load, circuit type, and applicable technical standards.

In addition to providing immediate protection, electrical devices also contribute to sustainability and resource efficiency. By preventing equipment damage and reducing the occurrence of fires, they minimize material and financial losses, as well as reduce energy waste.

Beyond their primary function of preventing accidents and damage, electrical protection devices are essential for facilitating maintenance and repairs in existing installations, as they allow for the safe and controlled interruption of power flow in the workplace, ensuring that professionals can carry out their activities without the risk of electric shocks or accidental re-energization of the circuit.

I believe it is clear how important it is to use protective devices in electrical installations. But before we go any further, below is a table showing the most common types of faults.

| Electrical Current – Terms and Definitions | ||

|---|---|---|

| Term | Definition | Example |

| Overcurrent | Any current exceeding the rated value. | Overload currents, fault currents and short-circuit currents are all different types of overcurrent.

|

| Overload Current | An overcurrent occurring in a circuit that is electrically sound. | An excessive current that is drawn when a motor is used to drive a mechanical load that is beyond its design capability. |

| Fault Current | A current resulting from an insulation failure or from the bridging of insulation. | Current that flows when unintended contact occurs between any two conductors, e.g. active and earth. |

| Short-Circuit Current | A fault current resulting from a fault of negligible impedance between live conductors. | Current that flows when unintended contact occurs between phases, or between phase and neutral conductors. |

RCBOs: Intelligent Protection for Residential Electrical Installations

Modern electrical systems employ different categories of circuit breakers, each designed for specific applications. In most residential installations, RCBOs (Residual Current Circuit Breakers with Overcurrent Protection) stand out as the ideal solution by integrating three essential functions into a single device:

Earth leakage protection - Detects ground faults from 30mA onward, preventing electric shock hazards

Overload protection - Triggers when current exceeds predefined thresholds

Short-circuit protection - Instantly interrupts high fault currents

The key operational advantage of RCBOs lies in their selective protection capability. When installed in dedicated circuits - such as laundry room outlets, bathroom circuits, or kitchen wiring - they ensure only the affected circuit is de-energized during a fault. This feature delivers three fundamental benefits:

• Maintains power supply to all other household circuits

• Simplifies problem identification and localization

• Significantly reduces maintenance downtime

Below is an example of an RCBO.

Details fo the RCBO used as a example

Rated at 240V, 30mA, type A, C-Curve.

. 30mA - According to AS/NZS 3000:2018, all final subcircuits in residential installations must be protected by Residual Current Devices (RCDs) with a rated residual current not exceeding 30 mA and a maximum disconnection time of 0.3 seconds.

The 30 mA threshold is internationally recognised as the maximum current that can pass through the human body without causing serious injury under typical conditions. It provides effective protection against electric shock by disconnecting the power quickly in the event of a fault. The 0.3-second (300 ms) trip time ensures that the circuit is interrupted rapidly enough to minimise the risk of ventricular fibrillation or other potentially fatal outcomes, especially in wet areas or when direct contact with live parts occurs.

. Type A - are designed to detect both alternating current (a.c.) and pulsating direct current (d.c.) leakage currents. This makes them suitable for protecting modern electronic appliances—such as washing machines, induction cooktops, and LED lighting systems—which may generate smooth or pulsed d.c. residual currents that standard Type AC RCDs cannot reliably detect.

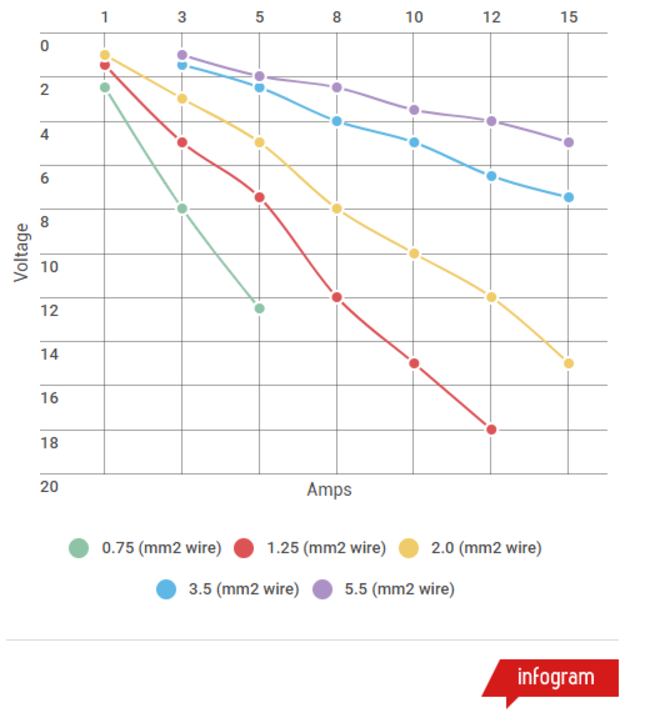

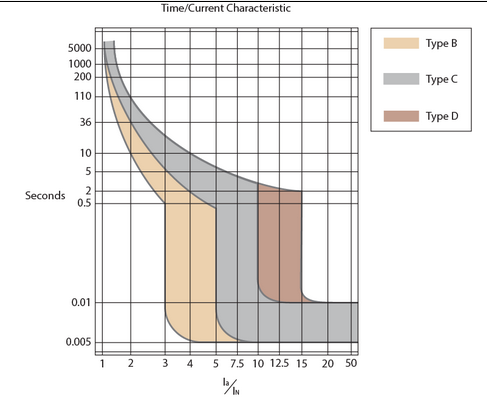

. C-Curve - C curve defines how the device reacts to high currents, especially short-circuit currents and inrush currents. The right curve (B, C, D, K, etc.) is crucial because:

C curve defines how the device reacts to high currents, especially short-circuit currents and inrush currents. The right curve (B, C, D, K, etc.) is crucial because:

-

It prevents unwanted tripping in equipment with high starting current (such as motors, compressors, transformers).

-

It ensures rapid protection in the event of a short circuit.

-

It defines compatibility with the load being protected.

Practical Examples of Application of the C Curve

| Parameter | Example 1: LED Lighting and Sockets | Example 2: Air Conditioner Motor |

|---|---|---|

| Circuit Breaker | 16A Curve C | 20A Curve C |

| Normal Current | ≤16A | 16A |

| Inrush Current | Very low (no significant peak) | 80A (4× In) for 0.5 seconds |

| Short Circuit | 80A–160A (5×–10× In) → opens instantly | 80A is below magnetic trip (5× In = 100A) |

| Overload Behavior | 20A (1.25× In) → trips in a few minutes | 80A in thermal zone → trips in ~1–3 seconds |

| Issue | No issue | May trip before motor fully starts |

| Recommendation | ✅ Suitable as is | ❌ Use Curve D (10–20× In) or increase to 25A Curve C |

HRC fuse

Fuses are essential components in electrical installations because they protect circuits and equipment against overcurrents (overloads and short circuits). They act as safety devices, interrupting the current when it exceeds a safe value, preventing:

Fires due to overheating of cables.

Damage to equipment (motors, electronics, transformers).

Risks of electric shock due to insulation failures.

Below is an example of an fuse.

Main Functions of Fuses

1 Short-Circuit Protection

-

When a short circuit occurs (e.g., wires touching), the current surges to hundreds or thousands of amps.

-

The fuse melts and opens the circuit in milliseconds, preventing serious damage.

2 Overload Protection

- If a device draws more current than it can handle (e.g.: a stalled motor), the fuse will blow after a while, preventing overheating.

3 Selectivity (Protection Coordination)

- Fuses can be used in cascade (e.g.: one in the main panel and another in the specific circuit) so that only the fuse closest to the problem operates, keeping the rest of the system energized.

4 Protecting Sensitive Equipment

- Ultra-fast fuses (such as in electronics) prevent components from burning out before a circuit breaker even reacts.